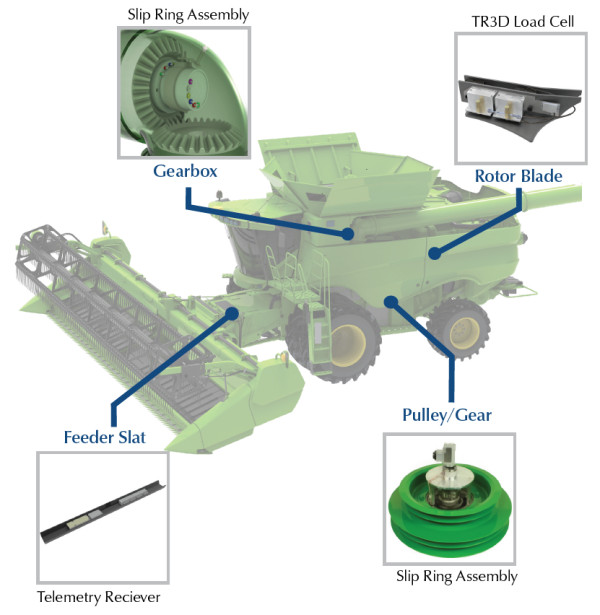

Harvesters include systems for several harvesting operations. Testing the operation of these systems can lead to greater fuel efficiency and productivity. Michigan Scientific produces precision testing instruments designed to measure losses in every component of the system to determine where improvement is possible. Recommended products are outlined in this chapter, and customization is available to fit any component.

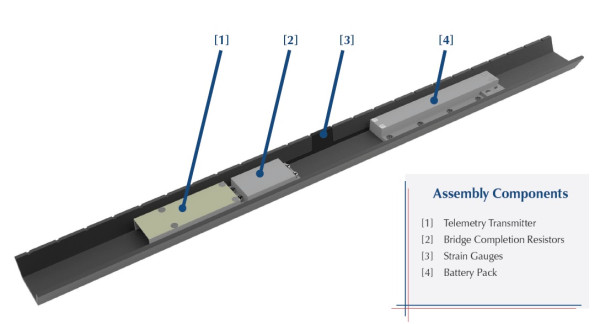

Feeder Slat

Instrumentation of a feeder slat can provide insights into the efficiency of the system. The speed and pitch of chain-and-slat conveyers can heavily influence fuel effiency and grain losses. Understanding the forces experienced by slats can provide crucial insight for development and validation.

Telemetry Transmitter and Custom Gauging

Michigan Scientific has experience using strain gauges to get measurements from OEM parts. After custom gauging has been installed on a part, our telemetry transmitter can be utilized to get those measurements to a DAQ device. Michigan Scientific telemetry transmitters are used in both laboratory and field testing.

Pulley/Gear

When evaluating performance, knowing the torque and speed and temperature of pulleys and gears offers crucial insight effeincy. Using strain gauges and thermocouples to instrument OEM parts allows for real-world measurements. Slip rings are a reliable solution for getting these measurements to a DAQ device, in both laboratory and field tests.

Slip Ring Assemblies and Custom Torque Transducer

Michigan Scientific can instrument pulleys and gears, including the gear teeth, to test speed, torque, strain, and temperature they experience when in use. These instrumentation solutions can be used for long-term test during general use or for specific test conditions with unknown conditions. Michigan Scientific Slip Rings are a reliable and durable method used to transfer data from the part to a DAQ system.

Gearbox

The elbow gearbox on an unloading auger is necessary for transferring harvested goods into a truck or cart. On a combine, the unloading auger adjusts its position to be over the transfer location. Gears power the auger to move harvested goods through the auger tube. Michigan Scientific precision instruments can test the speed, torque, and temperature of the elbow gearbox to see where improvements can be made for a more increased durability and efficiency.

Slip Ring Assemblies

The Michigan Scientific S-Series Slip Ring Assemblies are compact, allowing them to fit inside the elbow of the gearbox. This rotating signal transmission product is ideal for communicating the signal from the strain gauges on the rotating part to the stationary data acquisition.

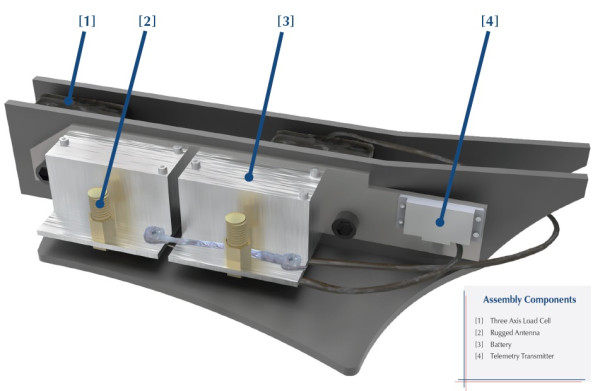

Rotor Blade

Rotor blades impact fuel efficiency as well as crop loss. Using multi-axis load cells offers a simple solution for measuring forces in rugged environments, such as on combine rotors. Telemetry can offer a solution to getting those measurements from the rotor to a DAQ device.

Three Axis Load Cells

Michigan Scientific offers a variety of load cells to meet load capacity and size needs. Our rugged Three Axis Load Cells can be used in harsh environments without sacrificing accuracy. Michigan Scientific telemetry transmitters can be utilized to transfer measurements from the rotor.